There are a lot of different challenges within the Food Processing industry when it comes to the use of HMI products such as working with oily produce and then having to work touchscreens, or the requirement of having no particle/food traps so that the use of the machines themselves are not the reason for contamination in the workplace.

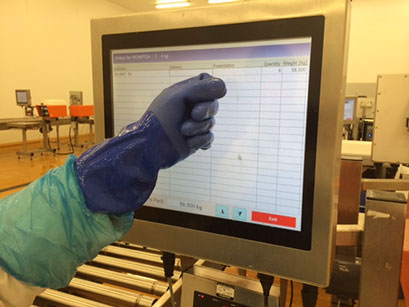

Ocean Fish using our 17″ IPC with PCAP

We tackle these challenges head on with our range of IP68+ sealed Industrial PCs, with flush projected capacitive touchscreens, protected by a tough 4mm polycarbonate filter, and stainless steel enclosures. Our trackspad type keyboards are well suited leaving no gaps that allow ingress.

The biggest importance in this industry is keeping a high level of hygiene and one of the major advantages of our sealed industrial products in the food processing industry is that they are easy to clean/wash down. This gives you the peace of mind in knowing that you are able to clean your product without effecting the known reliable performance.

Another importance in the industry is energy efficiency, which is why we aim to keep our products as energy efficient as possible using low power industrial components, whilst still giving you all the processing power you need to get the job done quickly and efficiently.

Some of the time our units are required to work in cold stores as low as -30°C. This would prove to be an even bigger challenge for a standard commercial PC however our Industrial Computers come with the option of adding an extended operating temperature range with the use of an internal heater. The internal heater is monitored and controlled by our watchdog which continuously monitors internal temperatures to adjust fan speeds and/or heaters.

This is why some big names such as Ocean Fish and Systems Integration have continued to use our industrial products over several years.

Recent Posts about Food Processing Industries: